Tank Engineering Design and Detailing Services

Tank engineering, design, and detailing services ensure safe, efficient, and compliant storage solutions

Tank Engineering

Introduction to Tank Engineering, Design, and Detailing Services

When it comes to storing liquids or gases, whether for industrial, agricultural, or domestic use, the design and engineering of storage tanks play a critical role. Our tank engineering, design, and detailing services ensure that your storage solutions are safe, efficient, and compliant with international standards. Tanks are utilized in industrial, agricultural, and domestic applications for storage purposes. In industrial settings, such as oil and gas, chemical manufacturing, and water treatment, tanks store raw materials, intermediates, and finished products.

In agriculture, farmers rely on tanks to store water, fertilizers, and other essential liquids for their operations. Domestically, tanks are used in residential areas for rainwater harvesting, septic systems, and fuel storage.

Global Engineering Standards

As experts in tank engineering, design, and detailing services, we are dedicated to meeting the highest industry standards. Our commitment to excellence is reflected in our adherence to engineering standards that vary based on geographical locations and country-specific regulations. This ensures that our solutions are reliable, safe, and compliant with local requirements. In the USA, we rigorously follow standards such as API 650, which covers welded tanks for oil storage, API 620 for low-pressure tanks, UL 142 for steel aboveground tanks for flammable and combustible liquids, and AWWA D100 for welded steel tanks for water storage. These standards are crucial for ensuring the structural integrity and safety of the tanks we design and build.

Global Engineering Standards

In the UK, we follow BS EN 14015 for designing and manufacturing above-ground welded steel tanks, S 799-5 for vertical cylindrical welded storage tanks, and PD 5500 for unfired pressure vessels. In the Middle East, we adhere to SAES-D-100 for atmospheric storage tanks, SAES-D-105 for hydrocarbon pressure storage spheres, and SAES-D-107 for water and wastewater tanks. In Australia, we comply with AS 1692 for steel tanks for flammable liquids and AS 1940 for their storage and handling. These standards ensure our tank solutions are safe, compliant, and tailored to each region's requirements.

Benefits of Professional Tank Engineering Services

Professional tank engineering services offer a multitude of benefits that can significantly impact the functionality and safety of your storage systems. Firstly, these services ensure that your tanks comply with all relevant international standards, helping you avoid potential legal and safety issues. This compliance is crucial in maintaining the integrity and reliability of your storage systems, as adherence to standards guarantees that the tanks are built and maintained according to the best practices in the industry.

Proper design and engineering enhance the safety and efficiency of storage tanks. By using advanced techniques and materials, professional services create tanks that exceed safety requirements, reducing risks like leaks and structural failures. This protects both personnel and the environment. Efficient tank design also improves operations, reducing downtime and maintenance costs while boosting productivity. Additionally, professional tank engineering services offer custom solutions tailored to specific storage needs, whether for chemicals, water, or other materials. These solutions optimize tank performance, maximizing capacity and efficiency while minimizing potential issues.

Who We Are in Tank Engineering, Design, and Detailing Service

Whether it’s a large-scale mega project, complex machinery with thousands of moving parts, or the most intricate of services that cannot clash, Edanbrook Consultancy Services has the capacity, systems, skills, and capabilities to deliver your entire modeling and detailing project. By turning complex data streams into intelligent and context-rich models, we are able to reduce costs and schedules while ensuring scheduling certainty confidently.

Our Expertise and Capabilities

With the Edanbrook team, you gain instant access to over 800 modeling, detailing, and digital engineering professionals worldwide, comprising an unparalleled blend of highly skilled experts and low-cost resources. There’s no need for you to engage multiple companies. Instead, if a scope stretches beyond our capacity, we have excellent relationships with the top industry partners that we employ. For you this means a single point of contact, zero potential of scope overlap, and less overall management.

Versatile, Streamlined Tank and Vessel Detailing

Experienced in the process design and layout of complex industrial plants, Edanbrook offers solutions to support all phases of the project lifecycle, from conceptual design to the management of assets. Our tank and vessel solutions form part of what is a complete suite of integrated, multi-disciplinary solutions offered across all industries and sectors. Our collaborative, multi-platform approach ensures maximum collaboration and productivity with the common goal of zero rework. Our tank and vessel designers have extensive experience in the design, fabrication, and construction phases of a project. Utilizing our expertise and the latest integrated software solutions and processes, we deliver a quality, cost-effective service for a wide variety of industrial process storage solutions.

Tanks & Vessels – Design to Manufacture

Our Deliverables

Fully Intelligent 3D Modeling

Highly accurate, intelligent 3D models used for the production of all drawings, bill of materials, weights, and cost data Piping systems and subsystems for pumping and multi-level sampling Rectangular and circular hatches, manways with davit arms, cleanouts, vents, couplings, and nozzles with flanges, elbows, and other attachments Scaffolding, access platforms, cable tray supports Lifting lugs, grounding lugs, baffles, liquid level gages, and gage poles.

Highly Accurate 2D Drawings and Project Documentation

Layout fabrication and erection drawings, bill of materials, plate cut data, and cost reports Detailed assembly and component fabrication drawings for all substructures, appurtenances, ladders, platforms, stairs, and other subsystems Plate layouts and fabrication details for shells, floors, and all roof types Shell weld maps, and shell roll out drawings overlaps and welds types NC, DXF, and scribing outputs

Enhanced Services Laser Scan, Virtual Assembly, and Geometric Validation

Accurate as-built 3D records of fabricated items can confirm the quality of fabrication and geometric conformance prior to delivery to the site and following installation. This can help reduce time, costs, and risks associated with traditional physical trial assembly as well as acting as a record of quality at the time of shipment.

We offer a number of laser back scan modeling solutions across all disciplines. These solutions have many applications and can provide accurate existing condition modeling where integration to existing plants is required, as well as a number of geometric verification and validation options when using point clouds for virtual trial assembly and tolerance reporting.

Designing API 650, 620 Tanks and Compliance Guidelines

Designing API 650 Tanks

Atmospheric Pressure Non-Refrigerated Tanks are required to be designed to withstand atmospheric pressures without the need for refrigeration. These designs must adhere to the guidelines established by API 650. Closed Top Tanks with Low Pressure need to comply with API 650 guidelines. Additionally, they must meet the requirements specified in Appendix F for low-pressure conditions. Higher Pressure Tanks operating up to 15 psig must comply with the standards of both API 650 and API 620 to ensure safety and reliability.

API 650 Material and Examination Requirements

Material Selection Criteria require that materials be chosen based on factors such as temperature, pressure, and the chemical nature of the stored substance. Examination Requirements mandate regular inspections and examinations, including radiographic testing, to ensure tank integrity.

API 620 Compliance for Higher Pressure Tanks

Design and Construction Requirements include stringent guidelines for materials, design, and welding processes to handle higher pressures. Material and Examination Requirements specify that API 620 tanks must undergo rigorous testing and examination to meet safety standards.

Appendix F for Low-Pressure Tanks

Additional Requirements for Closed Top Tanks include extra guidelines in Appendix F for tanks under low pressure, ensuring they can handle the slight internal pressures safely.

Appendix A for Tanks with Wall Thickness Up to 0.5 Inch

Material Restrictions Below 20°F indicate that certain materials are restricted below specific temperatures to prevent brittleness and failure. Additional Design Considerations include joint efficiency and spot radiography to ensure structural integrity.

Appendix J for Shop Assembled Tanks

Spot Radiography Requirements ensure that welds meet quality standards, which is crucial for tanks assembled in shops. Joint Efficiency Standards require maintaining a joint efficiency of 0.85 for shop-assembled tanks to ensure safety and durability.

Why Choose Edanbrook Consultancy Services

15+ Years of Experience

Bringing years of experience to the table, We are well-versed in handling international projects. We possess the requisite systems, expertise, and resources to ensure the punctual and effective execution of your project.

Uncompromised Accuracy

Our commitment to uncompromised accuracy extends across all facets of our engineering services, guaranteeing clients unparalleled quality and dependable results.

Dedicated & Experienced Team

our dedicated and experienced team is the backbone of our success. Comprising seasoned professionals with a wealth of knowledge in their respective fields, our team is committed to delivering excellence to our clients in every aspect.

Commitment to Timely Delivery

We'd like to make sure that your project is finished on time. Completing the design early and ensuring its accuracy helps us ensure when things will be completed. This expedites the start of construction and ensures that your project is completed on time.

Project Efficiency

Our team of seasoned engineers employs cutting-edge methodologies and innovative solutions to optimize project workflows, reduce costs, and improve overall efficiency.

Cutting Edge Technology

Thought and tool innovation (including Tekla, Prosteel, Revit, Plant 3D, Navisworks, and I Construct) are essential to our approach and critical to the accuracy of your project.

Portfolio

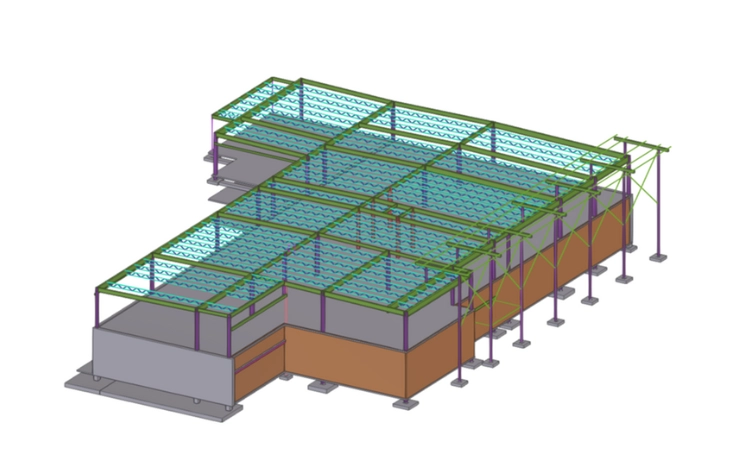

Building Type: Alabama Power - J9 Field Training Building

Location : Location -USA

Project Description

Alabama Power is a company dedicated to providing reliable and affordable energy to its customers. Edanbrook was brought on board to assist ith the engineering detailing. We released the approved package without a hitch. The Client authorized our package without any issues. We successfully finished the entire Fabrication package to the Client's specifications.

Read more

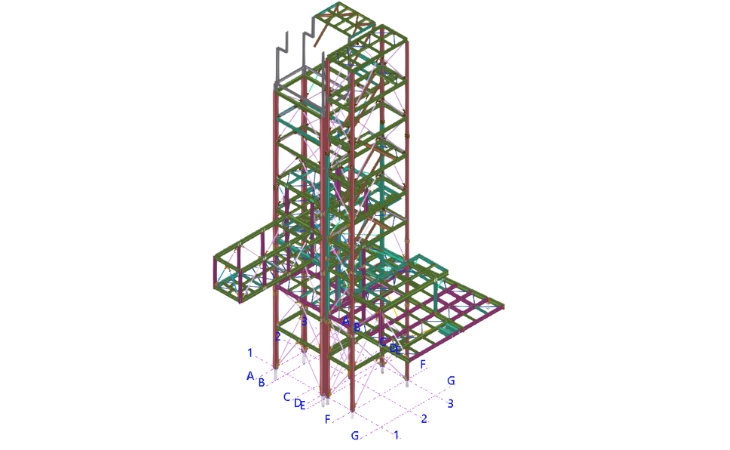

Building Type: 3DC-RTIO

Location : WESTERN AUSTRALIA

Project Description

Our Client plans to upgrade an existing mine facility by installing a new duct route and a steel building. Edanbrook Was brought on board to provide the tailed engineering and fabrication drawings. The technical team originally had problems while collecting inputs and had to deal with technical concerns, but they effectively overcame the obstacle because of their domain expertise. We delivered accurate structural drawings to our client.

Read more

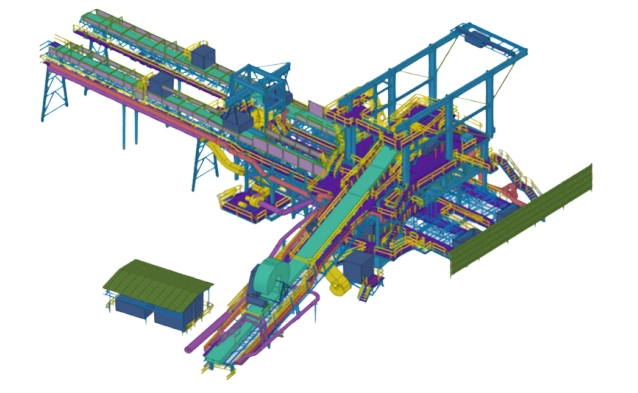

Building Type: High-Grade plant escape tunnel LOD 300

Location : WESTERN AUSTRALIA

Project Description

HIGH-GRADE PLANTESCAPETUNNEL is a challenging project. Our client plans to upgrade an existing mine facility by installing a new duct route and a steel building. The input came in the form of a point cloud model. And for the LOD 300 stage, we have a one-week lead time. All steel constructions, mechanical and plumbing, and plate work are included.

Read more