Cast In-situ Concrete Services

Boost your construction projects with precise in-situ concrete services from Edanbrook.

Cast In-Situ Concrete in Modern Construction

Comprehensive Cast In-Situ Concrete Services

Cast-in-situ concrete, or cast-in-place concrete, is the backbone of modern construction projects. This versatile building material offers unparalleled flexibility, structural integrity, and cost-effectiveness, making it a cornerstone in the construction industry.

Cast in-situ concrete refers to casting concrete directly at the construction site rather than precasting it elsewhere and transporting it to the location.

This approach is commonly employed for constructing foundations, walls, and floors. Additionally, in-situ concrete proves valuable when transporting materials, which poses challenges,

such as in specific building sites or underground construction projects.

Advantages of Cast in-situ Concrete

Flexibility in Design: Cast in-situ concrete allows architects and engineers to realize their creative visions easily. Its moldable nature enables the construction of complex shapes and structures, providing endless design possibilities.

Structural Integrity: Unlike precast concrete, in-situ concrete forms a monolithic structure, eliminating joints and potential weak points. That results in superior durability and resilience, ensuring long-term structural stability.

Cast In-Situ Concrete vs Precast Concrete

Cost-effectiveness: Seamlessly integrating in-situ concrete into construction processes reduces material waste and labor costs. Additionally, its longevity and minimal maintenance requirements translate to significant savings over a structure's lifespan.

Process of Pouring In-situ Concrete

Before pouring concrete, the construction site must be properly prepared, ensuring a level and compacted surface free from debris. Typically made of wood, steel, or plastic, formwork is erected to contain the concrete during pouring and curing. It serves as a mold for the desired shape of the structure. Concrete is mixed on-site using precise cement, aggregates, and water proportions. It is then poured into the formwork to achieve the desired shape and dimensions. After pouring, the concrete undergoes a curing process to optimize its strength and durability. That involves maintaining adequate moisture and temperature conditions for a specified period, typically from days to weeks.

The procedure for placing cast in-situ concrete encompasses several crucial stages

Maintaining quality control is essential throughout the entire process of working with in-situ concrete. Various tests, including slump and compressive strength, ensure the concrete meets specified standards and requirements. Monitoring factors such as temperature, humidity, and curing time helps identify potential issues early, allowing for timely corrective actions. Strict adherence to quality assurance protocols minimizes the risk of defects and ensures the longevity and safety of the finished structure.

Applications of Cast In-situ Concrete

Residential Construction: Cast In-situ concrete is popular for residential projects due to its versatility and durability. It can be used for everything from foundations and floors to walls and driveways.

Commercial Buildings: Cast In-situ concrete offers the structural integrity and aesthetic flexibility required for commercial structures such as office buildings, shopping malls, and hotels.

Infrastructure Projects: Bridges, dams, and highways rely on the strength and durability of Cast In-situ concrete to withstand heavy loads and harsh environmental conditions.

Cast in-situ concrete finds widespread applications across various sectors of the construction industry

Challenges and Solutions

Weather Conditions: Extreme temperatures and inclement weather can affect the curing process and compromise the quality of the concrete. Proper planning and protective measures are essential to mitigate these risks.

Time Constraints: Concrete pouring is time-sensitive, requiring efficient coordination and scheduling to ensure the timely completion of projects.

Infrastructure Projects: Skilled labor is essential for executing the intricate tasks of working with Cast In-situ concrete. Training and education programs help develop a competent workforce that meets industry standards.

Despite its numerous benefits, working with cast in-situ concrete presents certain challenges

Environmental Impact & Future Trends

Sustainability Practices: Efforts such as incorporating recycled materials and optimizing mix designs reduce the environmental footprint of in-situ concrete projects.

Carbon Footprint Reduction: Compared to other building materials, in-situ concrete boasts a relatively low carbon footprint, especially when sourced locally and produced efficiently.

Future Trends in In-situ Concrete: The future of in-situ concrete is marked by technological advancements and innovative techniques aimed at enhancing efficiency and sustainability.

Environmental Impact & Future Trends

Technological Advancements: Advances in materials science and construction technology have developed high-performance concrete mixes and improved construction methods.

Innovative Techniques: From 3D printing to self-healing concrete, innovative approaches revolutionize the way in-situ concrete is utilized, opening up new possibilities for construction projects.

Learn More About Cast In Situ Concrete

Read More: Why Cast-in-Situ Concrete is a Game Changer for Modern Construction?

Why Choose Edanbrook Consultancy Services

15+ Years of Experience

Bringing years of experience to the table, We are well-versed in handling international projects. We possess the requisite systems, expertise, and resources to ensure the punctual and effective execution of your project.

Uncompromised Accuracy

Our commitment to uncompromised accuracy extends across all facets of our engineering services, guaranteeing clients unparalleled quality and dependable results.

Dedicated & Experienced Team

our dedicated and experienced team is the backbone of our success. Comprising seasoned professionals with a wealth of knowledge in their respective fields, our team is committed to delivering excellence to our clients in every aspect.

Commitment to Timely Delivery

We'd like to make sure that your project is finished on time. Completing the design early and ensuring its accuracy helps us ensure when things will be completed. This expedites the start of construction and ensures that your project is completed on time.

Project Efficiency

Our team of seasoned engineers employs cutting-edge methodologies and innovative solutions to optimize project workflows, reduce costs, and improve overall efficiency.

Cutting Edge Technology

Thought and tool innovation (including Tekla, Prosteel, Revit, Plant 3D, Navisworks, and I Construct) are essential to our approach and critical to the accuracy of your project.

Portfolio

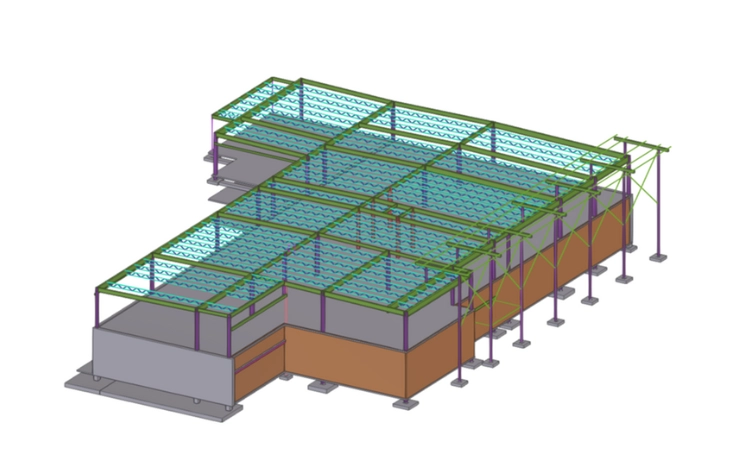

Building Type: Alabama Power - J9 Field Training Building

Location : Location -USA

Project Description

Alabama Power is a company dedicated to providing reliable and affordable energy to its customers. Edanbrook was brought on board to assist ith the engineering detailing. We released the approved package without a hitch. The Client authorized our package without any issues. We successfully finished the entire Fabrication package to the Client's specifications.

Read more

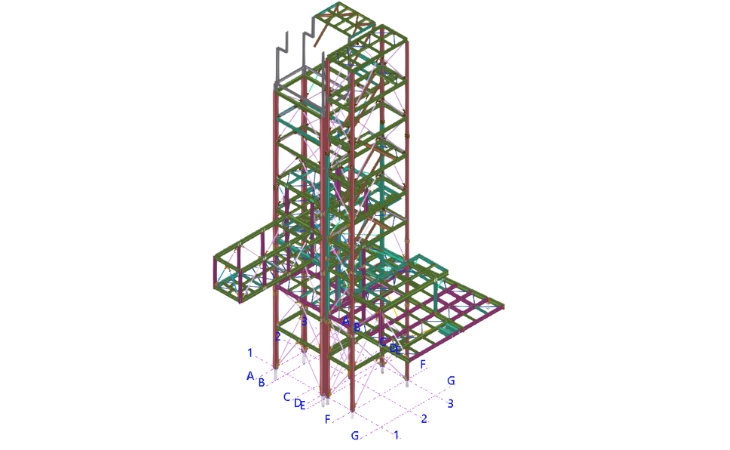

Building Type: 3DC-RTIO

Location : WESTERN AUSTRALIA

Project Description

Our Client plans to upgrade an existing mine facility by installing a new duct route and a steel building. Edanbrook Was brought on board to provide the tailed engineering and fabrication drawings. The technical team originally had problems while collecting inputs and had to deal with technical concerns, but they effectively overcame the obstacle because of their domain expertise. We delivered accurate structural drawings to our client.

Read more

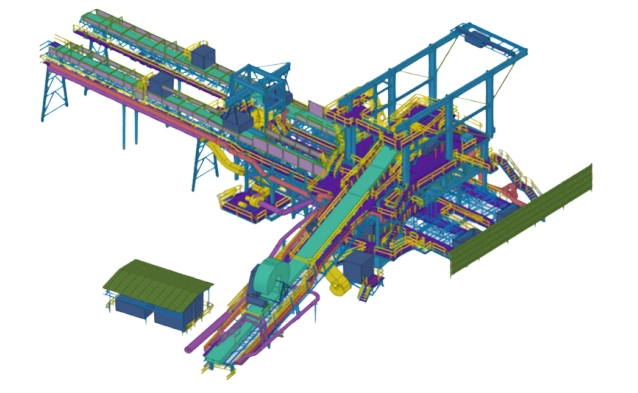

Building Type: High-Grade plant escape tunnel LOD 300

Location : WESTERN AUSTRALIA

Project Description

HIGH-GRADE PLANTESCAPETUNNEL is a challenging project. Our client plans to upgrade an existing mine facility by installing a new duct route and a steel building. The input came in the form of a point cloud model. And for the LOD 300 stage, we have a one-week lead time. All steel constructions, mechanical and plumbing, and plate work are included.

Read more